| Model | SCREW DIA(mm) MAIN / BABY | L/d RatioMAIN / BABY | SCREW RPMMAIN / BABY | TOTAL LOAD (KW)MAIN MOTOR (KW) | PRODUCTIONKg/hr. | DIMENSION L/W (MM) |

|---|---|---|---|---|---|---|

| CTS100 B125 | 100/125 | 29/112/1 | 60/75 | 12030/18.5 | 125-150 | 5700/1750 |

| CTS110 B140 | 110/140 | 29/112/1 | 60/75 | 13537/22 | 170-180 | 6200/1950 |

| CTS120 B140 | 120/140 | 29/112/1 | 60/75 | 14545/22 | 200-220 | 6500/1950 |

| CTS125 B150 | 125/150 | 29/113/1 | 60/75 | 15055/30 | 250-275 | 6950/2100 |

| CTS140 B160 | 140/160 | 29/113/1 | 55/75 | 20075/37 | 300-325 | 7750/2250 |

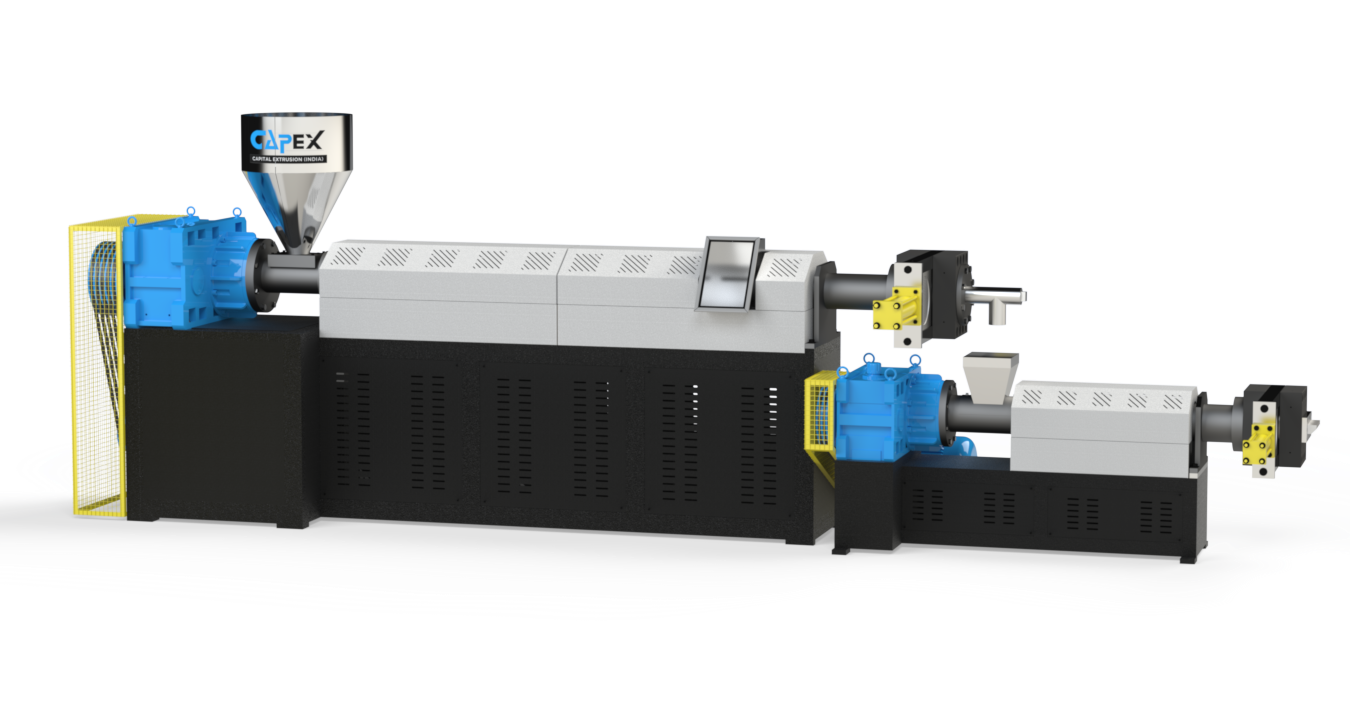

Capex CTS Series Two Stage Recycling Extruder represents the pinnacle of plastic recycling innovation, designed specifically for processors seeking maximum efficiency & superior output quality. Our advanced system transforms contaminated plastic waste into high-value recyclate through a precision-engineered two-stage process.

Contact our technical team today for a personalized assessment of how the CTS Series Two Stage Recycling Extruder can transform your plastic recycling operations. Demonstration facilities available for material testing.

Request Consultation