| MODEL | DIA(mm) | L/d Ratio | N (r/min) | POWER (KW) | PRODUCTION (Kg/hr) | |

|---|---|---|---|---|---|---|

| CMES-50/100 | CMES-50 | 50.5 | 24-48 | 500 | 45 | 100-350 |

| CE-100 | 100 | 7-20 | 85 | 30-37 | ||

| CMES-65/150 | CMES-65 | 62.4 | 24-48 | 500 | 75 | 200-500 |

| CE-150 | 150 | 7-20 | 85 | 37-45 | ||

| CMES-75/180 | CMES-75 | 71 | 24-48 | 500 | 110 | 100-800 |

| CE-180 | 180 | 7-20 | 85 | 45-65 | ||

| CMES-95/200 | CMES-95 | 95 | 24-48 | 400 | 200-250 | 700-1500 |

| CE-200 | 200 | 7-20 | 85 | 55-75 | ||

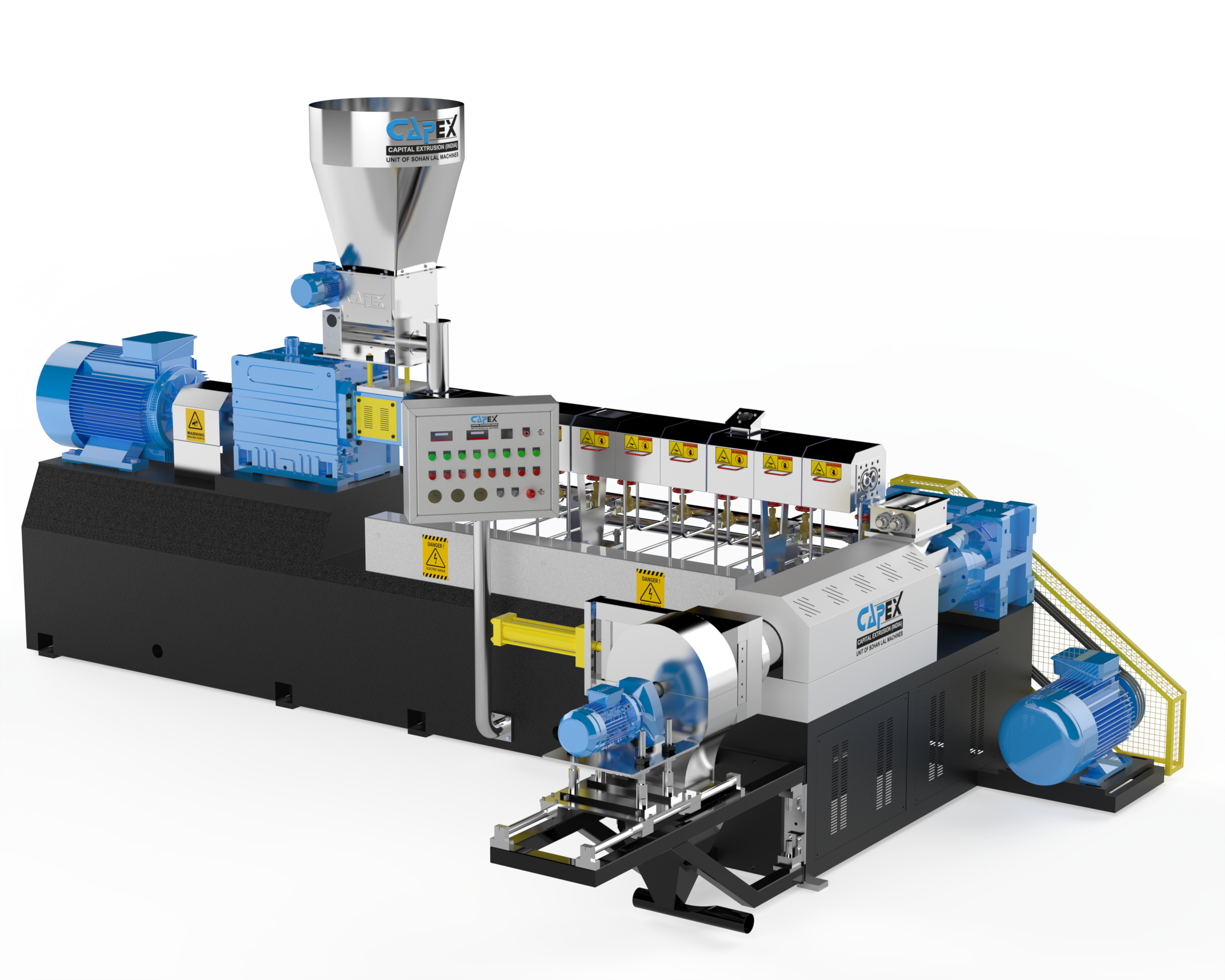

Revolutionary Two Stage Twin Screw Extrusion Technology

The CMES Two Stage Twin Extruder represents the pinnacle of extrusion engineering, designed specifically for manufacturers seeking superior processing capabilities and enhanced product quality. Our proprietary two-stage design maximizes efficiency while providing unmatched versatility across multiple industries.

Contact our extrusion specialists today to discuss how a CMES Two Stage Twin Extruder can transform your production capabilities and drive your business forward.

Request ConsultationCMES: Committed to Excellence in Extrusion Technology